The increasingly popular and exciting technology of 3D printing has rapidly advanced in terms of popularity and affordability. In the past, these printers were priced at exorbitant levels, but today, although high-end printers with advanced features are still expensive, there are now affordable options available for consumers. These printers are capable of creating a vast array of practical, creative, and entertaining objects.

The versatility of a home 3D printer is its most exciting aspect, as it can create a wide range of objects such as jewelry, ornaments, tools, cups, vases, napkin rings, and even articles of clothing. Artists can use it to design sculptures while parents and children can make toys. Additionally, there are special 3D printers available for printing edible items, both in consumer and professional versions.

To create a printable object, it must be first designed in a 3D art program, and then the printer is given the necessary information. Individuals can create their own unique designs or download designs from websites without requiring any artistic skills.

Alternatively, 3D pens can be purchased and are more affordable than printers. Although the resulting objects differ from those made by a printer, people are discovering new and creative ways to use these pens for creating three-dimensional art and sculpture.

How Do 3D Printers Work?

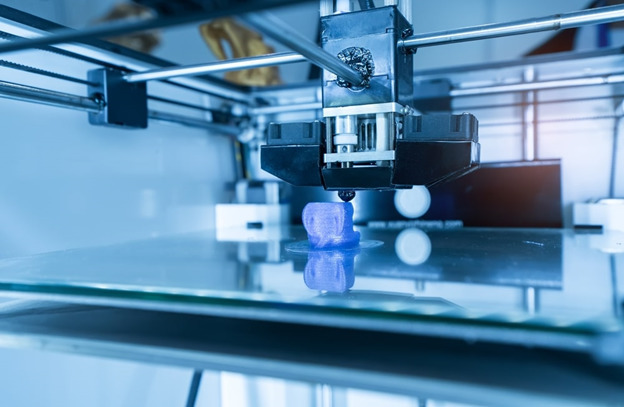

To create a 3D printed object, the initial step involves designing it using a 3D art, CAD, or animation program. The designed computer model is then saved as an STL file. A slicing program, the second program required, reads the STL file and converts it into G code, which directs the printer to create the object by forming a sequence of horizontal layers. The printer produces each layer separately, beginning from the bottom layer.

Professional printers can use a wide range of printing media, and while consumer-oriented printers usually rely on plastic extrusion or FDM technology, high-end FDM printers are available for purchase. The plastic filament is melted and extruded onto a platform in the printer, which solidifies immediately after being released from the extrusion nozzle. The nozzle moves in different directions to create the object, and the platform moves downwards as the object grows in depth. The plastic of each new layer fuses with the one beneath it, a process often referred to as additive manufacturing.

There are now 3D printers available at a price point similar to that of popular desktop ink printers. However, before purchasing one of these affordable 3D printers, it’s important to consider the features that are sacrificed in exchange for the lower cost, as well as the ongoing expense of purchasing plastic media.

Advancements Of 3D Printing In 2023

As we move further into the future, the technology of 3D printing is advancing at a rapid pace. With new materials, printers, and software being developed every day, the possibilities for 3D printing in 2023 are limitless.

One of the most exciting advancements in 3D printing in 2023 is the use of metal printing. While metal printing has been possible for a few years now, the process has been slow and expensive. However, new technologies such as binder jetting and metal injection moulding are making it easier and more cost-effective to print metal objects. This opens up a whole new range of possibilities for industries such as aerospace, automotive, and healthcare.

Another major advancement in 3D printing in 2023 is the use of carbon fiber printing. Carbon fiber is a strong and lightweight material that has been used in high-performance industries for years. However, until recently, it has been difficult to 3D print with carbon fiber due to its unique properties. With new advancements in printing technology, it is now possible to print objects made entirely out of carbon fiber, allowing for the creation of stronger and lighter objects than ever before.

In addition to new materials, 3D printing software is also advancing rapidly. In 2023, we can expect to see even more intuitive and user-friendly software that allows for greater control over the printing process. This will make it easier for individuals and businesses alike to create complex and detailed objects with ease.

Another exciting development in 3D printing is the use of bioprinting. Bioprinting involves using a special type of ink made from living cells to print 3D objects such as organs and tissue. While this technology is still in its early stages, it has the potential to revolutionize the healthcare industry by allowing doctors to print replacement organs for patients in need.

Conclusion

Overall, the advancements in 3D printing in 2023 are truly remarkable. With new materials, printers, and software being developed every day, the possibilities for 3D printing are limitless. Whether you’re in aerospace, automotive, healthcare, or any other industry, 3D printing is sure to play an increasingly important role in the years to come. So if you’re not already on board with this exciting technology, now is the time to start exploring all that 3D printing has to offer.