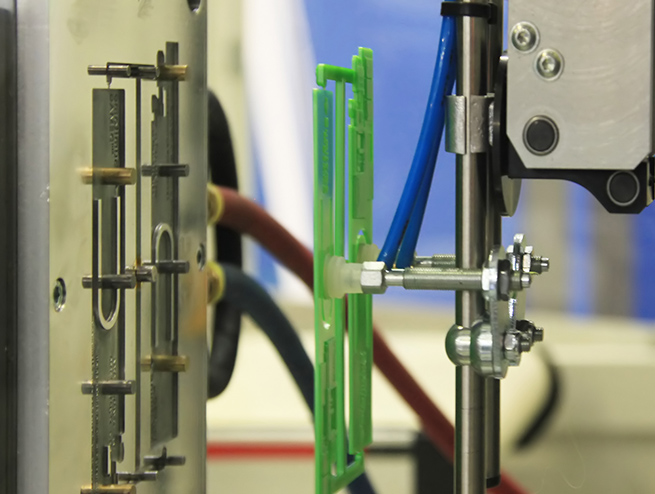

When it comes to designing a product, there are a few various approaches you may use… Injection moulding is one of the most common choices. There are several advantages to using plastic injection mold design, and we at Moulding Injection have direct experience with this technology.

However, you should always consider the whole picture before making a decision. That’s why we’ve outlined the advantages and disadvantages of injection moulding so you’ll be prepared.

Plastic Injection Mold Design Benefits

Speed and Efficiency – Time is of importance when it comes to large production. Injection moulding is an excellent alternative when you need to make a big number of items fast. Although the pace of output varies for every machine, they all create an astonishing quantity per hour. Injection moulding allows you to create a product in seconds rather than minutes or hours.

Flexibility – You will have total control and freedom over the design of your product, regardless of its complexity. Furthermore, injection molding solutions allows you to employ a variety of various types of polymers and colours to manufacture your item, allowing you to personalise it to your liking.

Consistency – In contrast to other manufacturing processes, injection moulding is unmatched in terms of efficiency. Every item manufactured is duplicated at every step, which is a major benefit in terms of mass manufacturing and quality control. It’s not important whether your design is simple or complicated; if your equipment is well-made and precise, your components will be fine.

Generates Less Waste – Brands are becoming increasingly ecologically concerned, and one of the best things about injection moulding is that it aligns with these principles. Injection moulding generates a little amount of waste.

Low Labor Costs – Because injection moulding is automated, you will save a lot of money on labour. A single operator can control all mechanics and robotics… You can essentially set it and forget it!

Injection Molding’s Drawbacks

Up Front Expenses – Because of the initial expenditures of the injection mould equipment required, injection moulding can be costly at first. Injection moulds are large pieces of steel with heating, ejection, cooling, and injection systems. However, for this initial investment, you will have a mould that will run consistently for a long time, creating components rapidly and cheaply.

Low Volume Production – Injection moulding is not a feasible solution for low-volume products. It isn’t cost-effective to put in the effort to construct the mould if only a handful of the pieces will be produced. Injection moulding should be used for mass manufacturing whenever possible.

Go For Fully Customised Plastic Chocolate Mold Design

Chocolate World moulds are widely recognised as among the best in Europe. These polycarbonate injection moulds come in hundreds of different patterns, ranging from basic pralines to intricate flat 3D sculptures. If you can’t discover precisely what you’re searching for, our staff can create a completely unique design for you.

When it comes to customized plastic chocolate molds, Moulding Injection can help you build whatever you can think of is chocolate. Almost any design may be turned into a be spoke polycarbonate mould by our staff, which has the skills and capabilities to do so. We can assist you with turning a basic logo into chocolate bits or creating a comprehensive 3D mould based on a napkin design.

If you’re unsure where to begin, our experts can assist you in determining which form of custom plastic molds for chocolate making is best for your needs. Determine the type of project you want to do!

If you’re thinking about using injection Frisbee for your product, we can provide you with all the information you need to make an informed decision and get started. Get in touch with us right away!