Plastic is said to be the most important and extensively used product in moment’s competitive terrain. It can be said that plastic has taken over the request and has converted the way companies suppose about plastic injection mould manufacturer products. This formative use, along with the continuity for everyday requirements of plastic, has assessed product conditions.

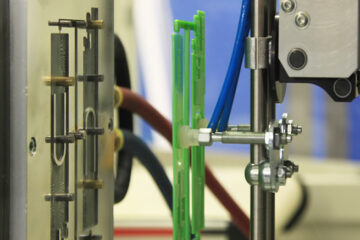

Compared to other mechanical procedures, it’s a veritably effective system that’s also veritably simple. A hopper feeds plastic grains into the insertion chamber of the machine. In this exertion, it’s important to insure that the bullets are harmonious and unevenly distributed. To insure that this phase is completed duly, the repaying screw is operated and covered. This phase establishes whether the plastic grains are equal. A stumbling block in the part.

Once this system has been duly estimated, the bullets are passed through a heating element to run or melt them. A snoot is fitted into the earth depression, and the plastic is fitted into the depression, where movable plates apply pressure to insure the material solidifies.

This is a truly protean approach to producing a wide range of simple to complex plastic corridor with an excellent finish. The beauty of it’s that, depending on the conditions, nearly any type of 2D or 3D shape can be created. Stamping is essential in utmost cases, as the shape must be removable from the earth. Side holes and threaded holes, on the other hand, are more likely to go unnoticed.

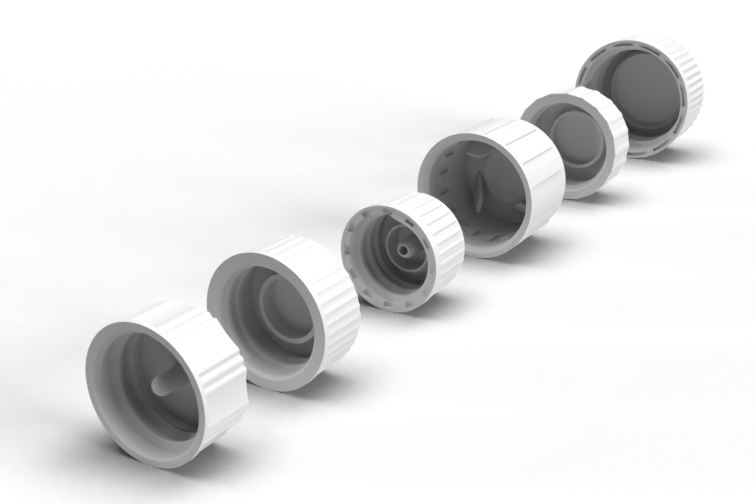

piecemeal from that, there are custom-made plastic molds, which are manufactured according to the client’s specifications and differ from the operations. The manufacture of molds for injection of molten liquid plastic into a series of set shape molds, which are also allowed to cool, is the base of Plastic Injection. The cost of the plastic tooling is low, but the cost of each part is high, which is why this product is classified as Plastic Injection earth Making.

The same amount of material is always injected into the mould at the same pressure and duration, as well as a variety of other characteristics, thanks to automated plastic injection mold design technology. The advantages and numerous uses of these technologies will be discussed in-depth in this medium post.

Mound molding using plastic injection molding

Mound molds are some of the most inconceivable pieces of manufacturing outfit available. In terms of engineering and art, a mound earth is a true work of art.

mound molds, in turn, indicate a high position of moxie from the perspective of a plastic earth manufacturer.

What’s the meaning of the term” mound earth”?

There are numerous variations on the subject of mound molds, still, then are some common characteristics

● Designed for high volume manufacturing runs.

● There’s a single depression with multiple cores.

● Capability to perform multiple operations throughout the molding cycle.

What are the prices of mound molds?

Mound molds are, in fact, relatively precious. thus, they bear a large volume to justify their price. This expenditure is accessible given the quantum of engineering and manufacturing that goes into the earth. The design and fabrication of a mound earth isn’t for the inexperienced mold maker or those who take lanes!

There are a number of advantages to mound molding. What are some of them?

For the manufacture of multiple plastic corridor, mound molding is a cost-effective and effective system. Injection Molding companies are always looking for new and advanced molding ways.

There are several advantages to using mound molding Plastic Injection Molding Parts, including Increased product effectiveness( productivity).

● Reducing the number of machines demanded.

● Producing doubly as numerous corridor with the same press size and clamp heftiness, which significantly reduces the price of corridor.

● Cost of set- up and running time is divided by the total number of corridor produced.

● The front and back corridor of a crucial ring are created at the same time.