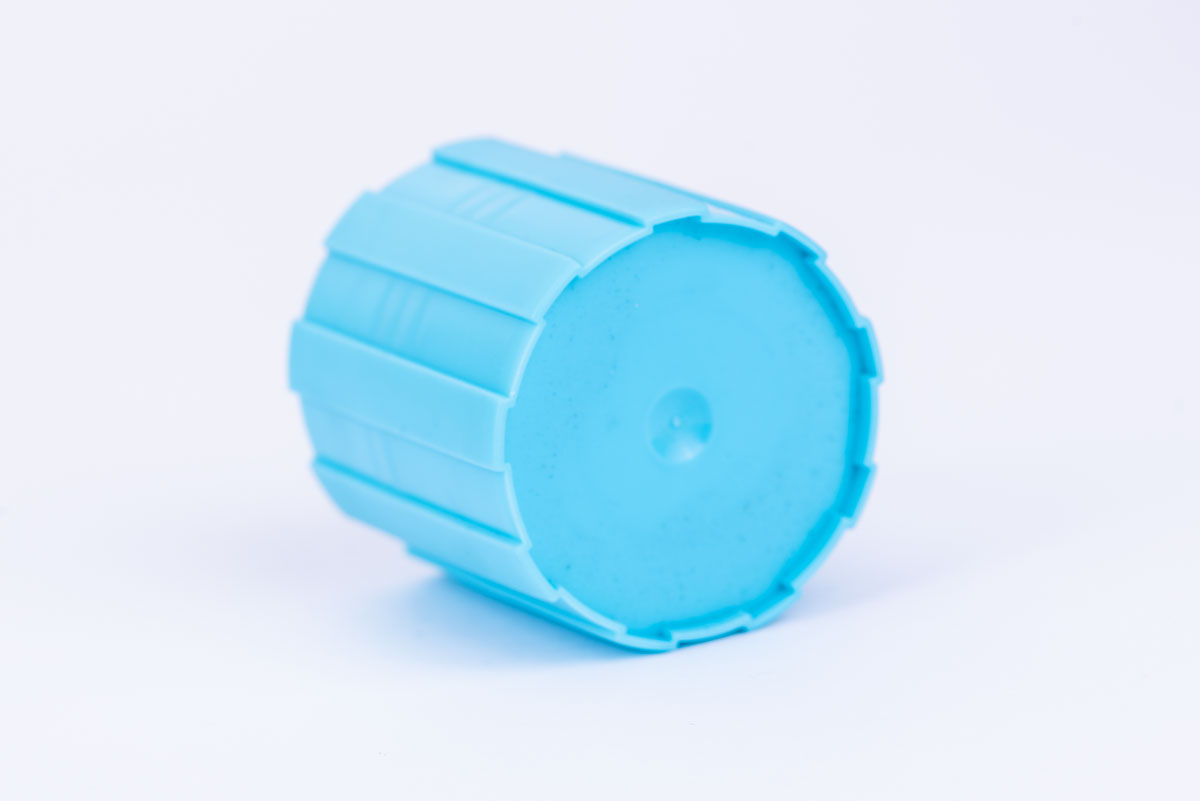

Plastic Injection Molding services are used by companies in a variety of sectors, including medical, automotive, retail, construction, and many more, to make the delicate components they require for a variety of purposes. Standard components, on the other hand, are insufficient for some tasks. Each project is reviewed by a custom injection mould manufacturer to determine the amount of customization required.

When Should You Use A Custom Injection Molder

There are a number of reasons why you would desire to hire a plastic injection molding manufacturer to ensure that your components satisfy your requirements:

When high levels of accuracy and tight tolerances are required

When certain safety requirements or industrial laws must be met

When you want to increase the mold quality, there are a few things you may do.

When you’re looking for strategies to save expenditures

When you’re working with intricate measurements and geometry, it’s important to stay organized.

When you are in a particular business or are in a circumstance where you need a manufacturer with a wide range of experience.

Just-In-Time Manufacturing Demand –

There are several advantages to designing items to satisfy your demand rather than generating a surplus. Just-in-time manufacturing boosts production and reduces lead times. It guarantees that your producing partner is invested in your success in order to ensure that you return to make another order, resulting in dynamic, high-quality designs,robust production, and quality assurance. Working with a full-service firm saves money since all stages of the project may be completed under one roof with one set of quality and safety requirements.

You save money by not having to maintain merchandise that may or may not be obsolete by the time you need it. Inventory control and manufacturing ensure that you have what you need when you require it.

Factors For A Successful Mold Making –

The mold is the foundation of your product’s success. Investing in a good mold ensures constant product quality and long-lasting components. There are a few aspects that all of the best plastic injection molds have in common:

Design and engineering that is both innovative and exact Mold cavities and bases are made of stainless steel. Manufacturing equipment that is modern and well-maintained A precision and accuracy-assuring mechanism It’s all in the small print. A well-built mold may survive for decades if you pay attention to the details.

Get The Custom Injection Mold You Need –

The injection moulding reduces down to a few simple steps:

One- Melt the plastic substance

Two- Inject the material into the metal mold in steps two and three.

Three- Let the material cool

Four- take the final object from the mold

Of course, in actuality, the procedure is a little more difficult. You may learn more about the plastic injection moulding process here.

Advantages of Custom Injection Molding –

The material utilised is one of the most crucial and beneficial features of moulding plastic items. There are several sorts of plastic materials, each with its unique set of qualities and strengths.

Do you require a long-lasting item that can tolerate frequent use? For that, there’s plastic. Are you looking for something flexible and food-safe? It’s no issue. A plastic injection mould manufacturer can help making custom molds with precise conditions.

Temperature tolerance, chemical resistance, and anti-abrasive characteristics are all options. This ensures that no matter what obstacles you confront, there is a material that can assist you to overcome them.

If you have a project that requires custom injection molding,contact the top plastic moulding manufacturers and visit https://www.moulding-injection.com/. Moulding-Injection is the premium chocolate packaging manufacturer and offers a wide range of products.